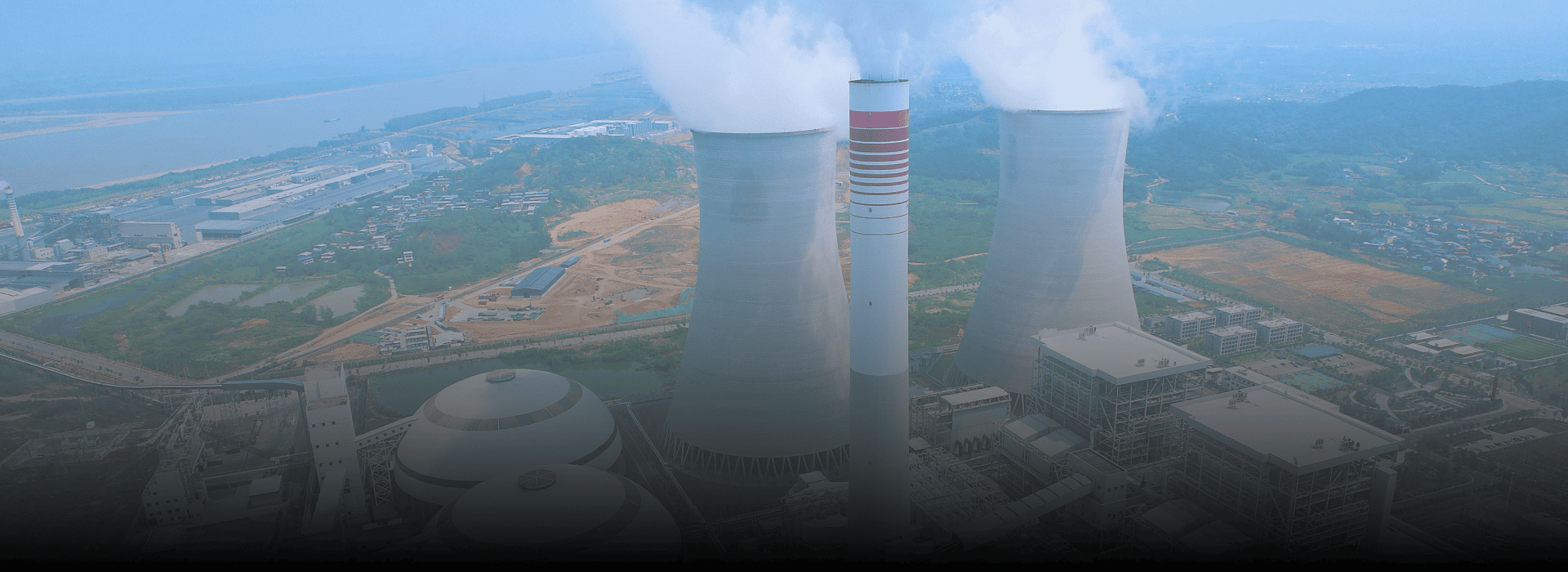

Plant engineering design refers to the multidisciplinary process of planning, designing, and optimizing an entire industrial facility or plant. This includes everything from the layout of equipment, piping systems, instrumentation, control systems, safety systems, structural elements, and utility networks ensuring the plant operates efficiently, safely, and in compliance with industry standards. In the Oil & Gas sector, this typically involves Refineries, Petrochemical plants, offshore platforms, Gas processing units, LNG terminals, Storage & distribution facilities etc.

Relevance in the Oil & Gas Sector

The oil & gas industry is undergoing major transformation, and plant engineering design is at the heart of that change.

Key Reasons It's Highly Relevant:

1.Aging Infrastructure Revamp : Many existing plants need revamping or debottlenecking to extend life and meet new regulations.

2.Energy Transition Pressures: New plant designs need to accommodate cleaner fuels like hydrogen, ammonia, biofuels, or integrate carbon capture (CCUS) technologies.

3.Safety & Risk Management : Complex hazard-prone environments demand robust design to prevent accidents and meet stricter HSE regulations.

4.Digitalization (Industry 4.0): Integration of smart sensors, automation, and digital twins requires plant designs that are flexible, data-driven, and compatible with new tech.

5.Global Project Delivery: Modular design and remote collaboration across countries is common, making smart plant design tools indispensable.

What Does Plant Engineering Design Involve?

- Process Design: Flow diagrams (PFD, P&ID), equipment sizing, material & energy balances

- Piping Design: Routing, stress analysis, pipe supports

- Mechanical & Structural: Equipment layout, platforms, supports

- Electrical & Instrumentation (E&I): Cabling, control panels, instrumentation layouts

- Safety & Fire Protection: Hazardous area classification, firewater systems

- 3D Modeling & Integration: Creating a virtual model of the plant for clash detection, simulation, and maintenance planning

Importance of Learning Piping Engineering Design Software

While plant design is broad, piping engineering software is one of the most essential subsets it connects process flow, equipment, and utilities.

1.Central Role in Projects: Piping systems make up 30–50% of project cost and are essential for transporting fluids. Their design is a critical path activity.

2.Software Drives Modern Design: Tools like AutoCAD Plant 3D, CADWorx,Smart Plant 3D (SP3D), PDMS/E3D, and CAESAR II help create detailed, error-free, and code-compliant piping layouts.

3.Minimize Errors & Rework: Piping layout issues like clashes, excessive stresses, or improper supports can lead to project delays or safety failures. Software helps catch these early.

4.Career Competitiveness: These tools are standard in EPC (Engineering, Procurement, Construction) firms. Mastery can significantly boost your job prospects in design and project engineering.

5.Supports Multi-Discipline Coordination: Integrates with civil, mechanical, E&I teams for a unified design environment especially critical for large-scale oil & gas projects.

Job Titles after learning Plant Engineering Design softwares

- Plant Design Engineer (Junior)

- CAD Engineer / CAD Designer

- Plant Layout Designer

- 3D Modeler – Plant Design

- Mechanical Draftsman – Plant Engineering

If you're looking to enter or grow in the Oil & Gas or process industries, learning plant and piping engineering design software is no longer optional it's expected. It’s a gateway to working on complex, high-budget, international projects and playing a key role in the energy future. We are always here to help you for achieving your requirement as we are one of the top piping engineering institute in Kerala/India providing best piping courses.